How to move products using Containers

Containers is a brand new feature that helps you track where your inventory is while moving products internally. It’s currently available when using replenishment advice, handling returns, and for manual stock transfers. In this post, we’ll walk you through how you can use Containers effectively in your warehouse.

A quick explanation of Containers

Moving products within your warehouse might take just one minute, or it might take several hours. During that time, your digital inventory in Picqer doesn’t match the physical reality. The products are no longer at the old location, but they haven’t yet arrived at the new one either.

With Containers, you can assign moved products to a “container.” This acts as a temporary location while you’re transferring items. That way, anyone in Picqer can see that the products aren’t at location A or B, but are currently in transit.

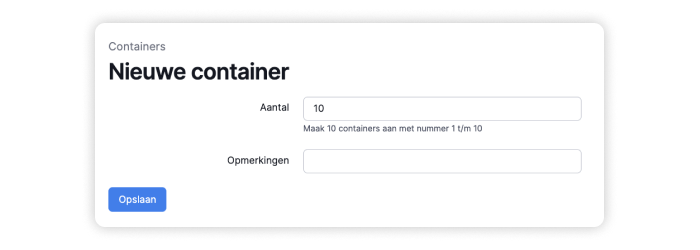

You choose how you move your products — using a cart, rolling rack, pallet, or even 100 small bins. In Picqer, you specify how many containers you have in your warehouse. You can also print barcode labels for your physical containers directly from Picqer.

Everyday use cases

Let’s say you want to move 50 items from bulk stock to your picking location using a rolling cart. By scanning the barcode on the cart as you move, you let Picqer know you're using that container for this transfer. You’ll now see in Picqer which products are in the container, sorted by pick location. When you reach the first pick location, scan the item as you take it out of the container. Picqer will then move it from the container to its new location.

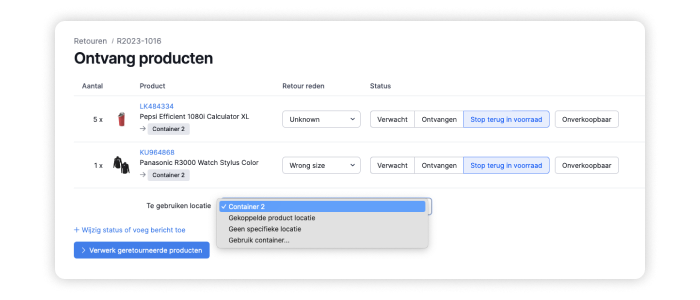

You can also use Containers when processing returns. For example, say 10 different orders are returned on the same day. To work efficiently, you handle them all at once. At the packing table, you check whether each product can be restocked, then place them in the container. You bring the container into the warehouse, and one by one, scan and return the items to the correct locations.

While products are in a container, they’re counted as part of your stock, but they’re not available for picklists. Once you move them out of the container and into a fixed location, they immediately become available again. This lets you move products at your own pace without worrying about someone trying to pick them mid-transfer. It also means you don’t have to manually update the locations afterward.

Moving large volumes of products

Sometimes transfers take hours. Maybe you're moving two aisles of seasonal products to the back of the warehouse, or filling a new rack with stock. In these situations, a large quantity of products is without a fixed location for a while. Meanwhile, a colleague might be running a stock count or creating a picklist.

Using Containers for these kinds of bulk moves keeps everyone informed. Your colleagues can immediately see that the items are in a container and in transit from point A to B. This means everyone always has the correct stock information, no matter how long the transfer takes.

The better Picqer knows your inventory, the better it performs

From the moment a product enters your warehouse until it leaves, you want your inventory to be as accurate as possible. With Locations, you always know where your products are. And now, with Containers, you also know what’s currently on the move.

At this stage, you can use Containers with replenishment advice, returns, and manual stock transfers. We’re actively working on support for using Containers during receiving. Ultimately, we want every internal stock movement in your warehouse to be done via a container — because the better Picqer knows your inventory, the better it works.

We’ll keep you posted in future blog updates. Want to get started with Containers for replenishment or returns? Here’s how to create containers.