Onboard new order pickers quickly with Picqer

It’s becoming increasingly difficult for webshops to find and retain warehouse staff. That’s why it’s important to be able to onboard new order pickers quickly so they can start contributing right away.

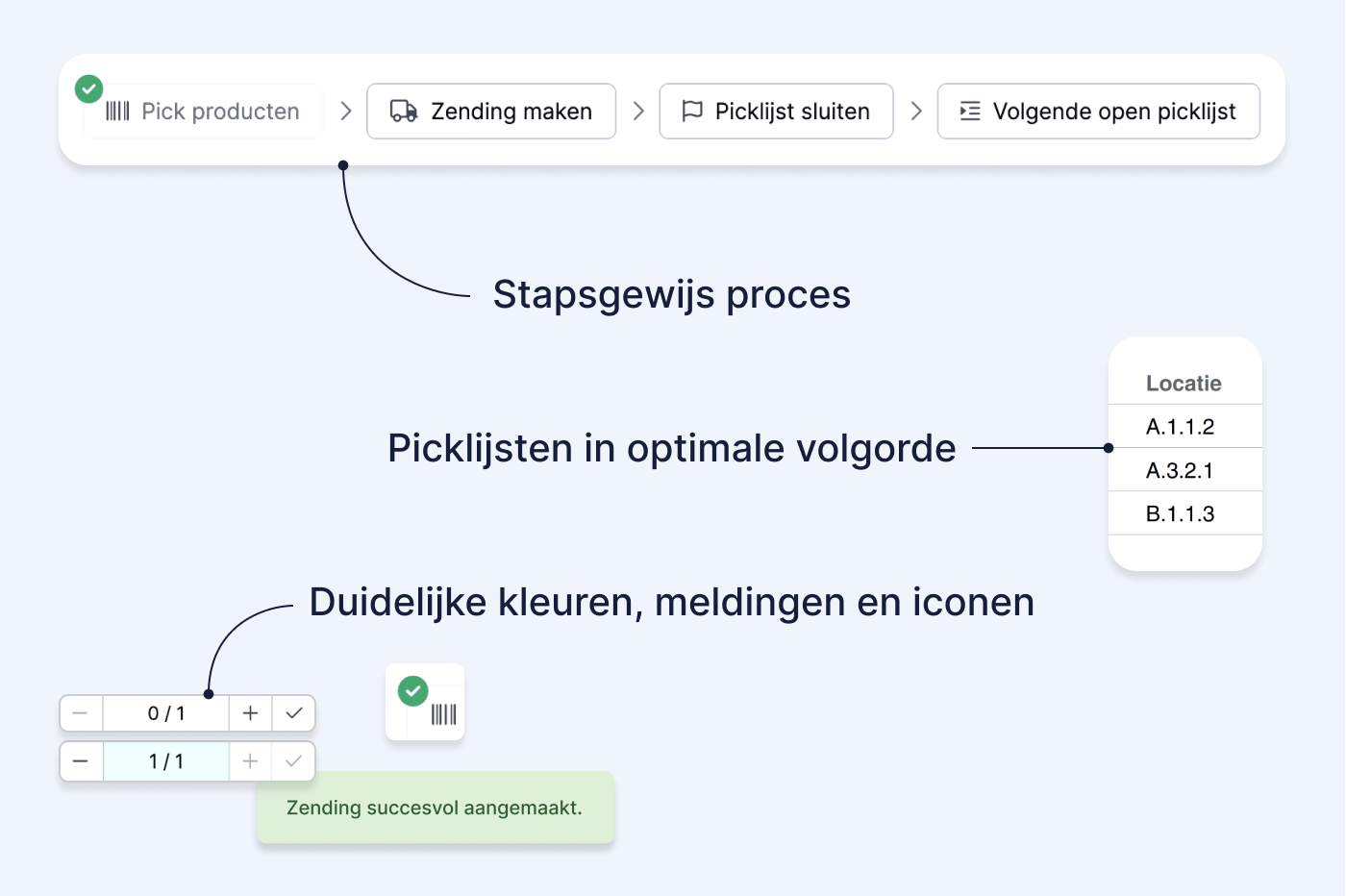

Picqer is built to make warehouse work as logical and simple as possible. The software guides users step by step, and the interface is designed to be clear and intuitive, using colors, alerts, and icons that anyone can understand. This allows anyone, with or without experience, to work independently in no time. In this article, we’ll explain how to use Picqer to onboard new order pickers in just a few minutes.

- We recommend using locations. When every location has its own number, Picqer can optimize the order of the pick list. The order picker can simply follow the list and doesn’t have to search for the right spot in the warehouse.

- If you're using barcodes, each product can be scanned. This makes it easier to pick products without requiring prior product knowledge.

- If you're using handheld scanners, order pickers can instantly check whether they’ve picked the correct product during both picking and packing.

Below, you’ll find an overview of the onboarding process for a new order picker, based on the setup described above. In this example, we use batch picking (multiple pick lists combined into one), since that involves the most steps. If you’re picking one list at a time, products are scanned only during the picking process. At the packing table, they can be packed immediately. Read more about the different picking methods here.

Ready to go with just one system

To start picking, simply open Picqer. There’s no need to log into other systems like your webshop, carrier, or stock system. Because everything is connected to Picqer, orders are imported automatically. Picqer checks whether the ordered products are in stock and creates a pick list—your to-do list for the day.

Picqer guides you to the right spot in the warehouse

You open the pick list on your handheld scanner (or print it, if you prefer). Picqer has already sorted the list to match your most efficient walking route. It tells you how many items to grab from each shelf and which container they should go into. You scan each product before placing it in the container, so you can be sure it’s the correct item.

A final check at the packing table

To complete the pick list, you scan each product one last time at the packing table. Picqer checks the order, and you double-check it visually. If anything’s off, you’ll get a message so you can make manual adjustments—for example, if an item is too heavy for standard shipping. Once everything checks out, Picqer prints the correct shipping label. You can pack the order and move on to the next pick list.