Walk less, process more orders

Anyone can run a webshop, no matter how much warehouse experience you have. You can sell products from anywhere — whether it's your garage, a corner of a shared space, or a full warehouse. The most important thing is knowing where all your products are, so you can pick and ship orders to customers quickly.

But what happens when your shop grows and you suddenly have to handle more than 50 orders a day? You’ll likely spend most of your time picking and packing, leaving little room for other important tasks like restocking or marketing your shop.

There’s a better way. In the video, Bob explains the benefits of a smart warehouse layout using locations and location numbers. He also shows how warehouse software helps you work even more efficiently, for example by picking multiple orders at once. That way, you can process more orders while walking less.

How locations and location numbers work

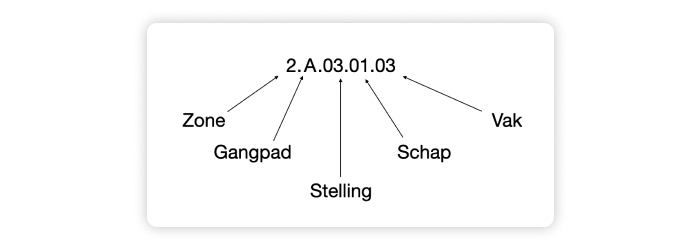

The places where products are stored in your warehouse are called locations — things like racks, shelves, and bins. Each of these locations gets its own unique number. It’s important to come up with a consistent system you can easily expand. For most people, an alphanumeric format like this works well:

You link these location numbers to your warehouse software. This allows the software to know exactly where each product is stored. Thanks to this setup, picklists can be automatically arranged in the most efficient order based on your warehouse layout. You no longer have to walk back and forth unnecessarily or return to the same spot multiple times. That saves you a lot of steps and time.

Pickers simply follow the list — they don’t need to remember where items are. And since they're picking based on location numbers, they don’t need any product knowledge either. Anyone can learn how to pick orders this way, and training new employees becomes quick and easy. That gives you more time for other important tasks.

The sooner you start using locations, the better

No warehouse is too small to benefit from locations. That’s why we recommend starting with location management as early as possible. The longer you wait, the more work it becomes to number all the locations and register them in the software. Read how to set up locations in Picqer.

Picking multiple orders at once

Working with locations already makes things more efficient. But if you’re using warehouse software, you can take it even further. In the video, Bob shows how you can pick multiple orders at once — this is called batch picking. The software creates a single, optimized picklist that combines products from multiple orders, sorted by their location in your warehouse. The picklist shows where each item is, how many you need to pick, and which product belongs to which order.

With batch picking, you can walk a smooth route through your warehouse. You’ll walk about the same distance as picking a single order, but you’ll process many more at the same time. Learn more about the different ways to use batch picking.