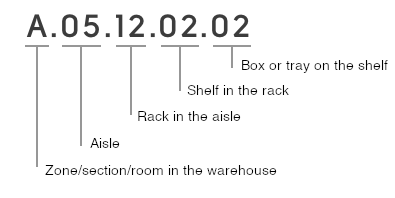

Optimize your warehouse layout

Every webshop owner wants to ship orders quickly. Optimizing your warehouse layout is one of the areas where you can save the most time. In a well-organized warehouse, you can pick the right products more easily, avoid running into each other, and maintain a calmer working environment.

Separate entry and exit

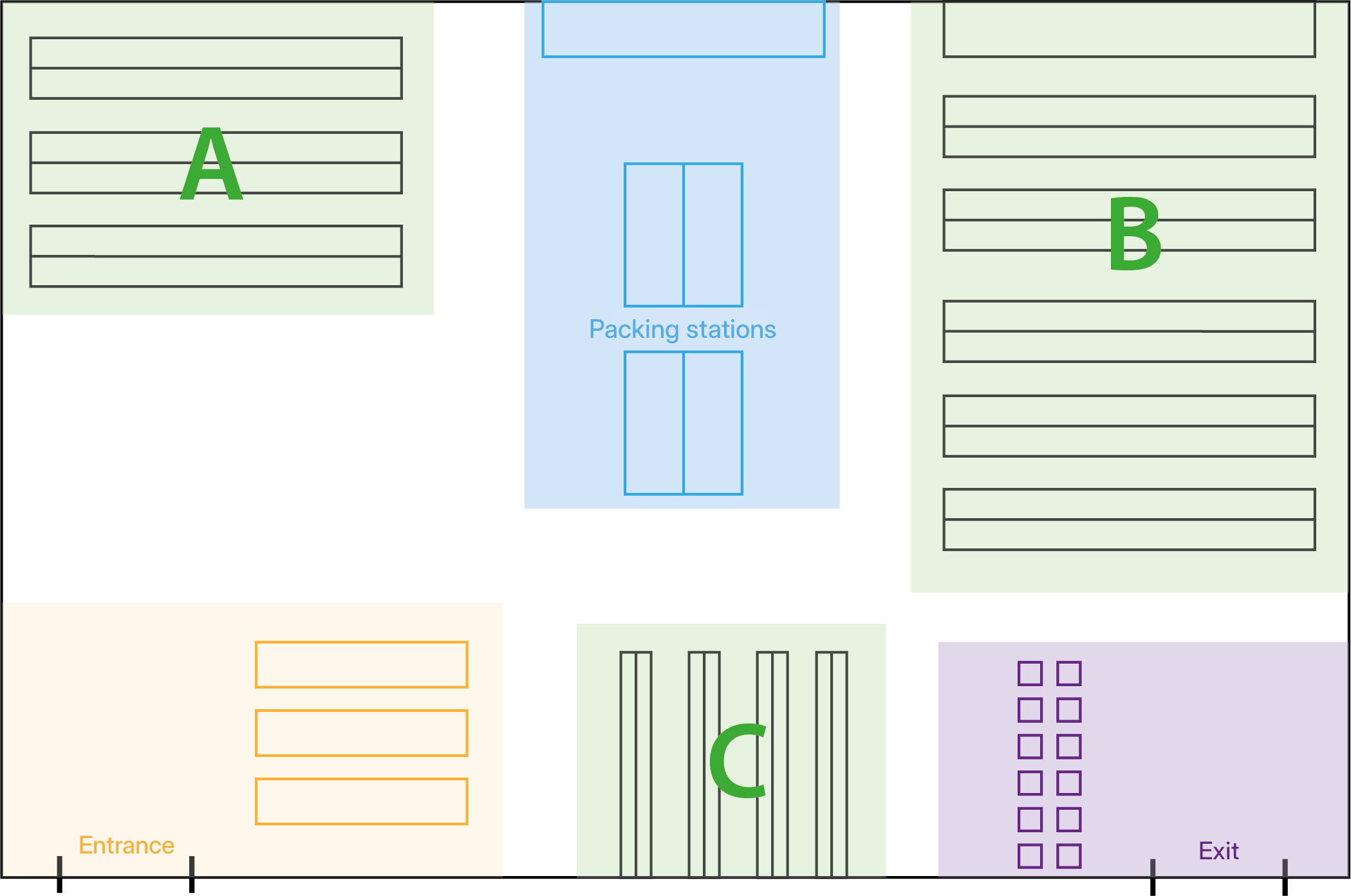

Warehouse layout depends on many factors, with the building itself being the most important. Often, you don’t have full control over this. If you rent a space, you have limited say in its dimensions and construction. Even when building your own warehouse, your budget plays a role. If possible, we recommend having a separate entry and exit.

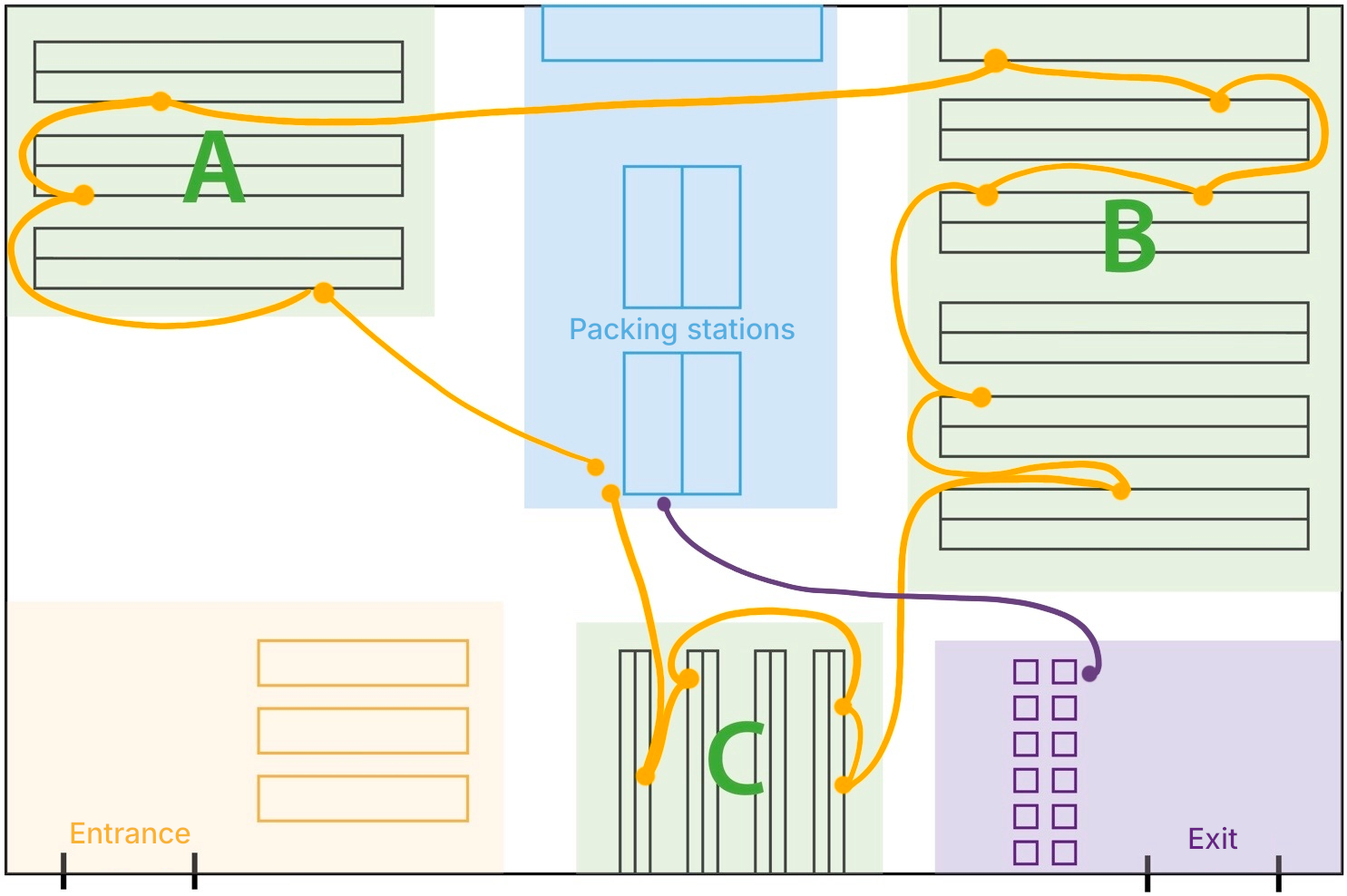

The image above shows how to organize a warehouse with separate entry and exit points. This setup allows you to keep incoming goods and outgoing orders separate.

At the entrance, you can set up a station to receive incoming goods. If you use multiple zones or floors, you can immediately sort products by zone using separate roll containers. This speeds up the storage process considerably.

At the exit, you can create space to place full roll containers before they go to the carrier. This keeps the rest of the warehouse organized and accessible.

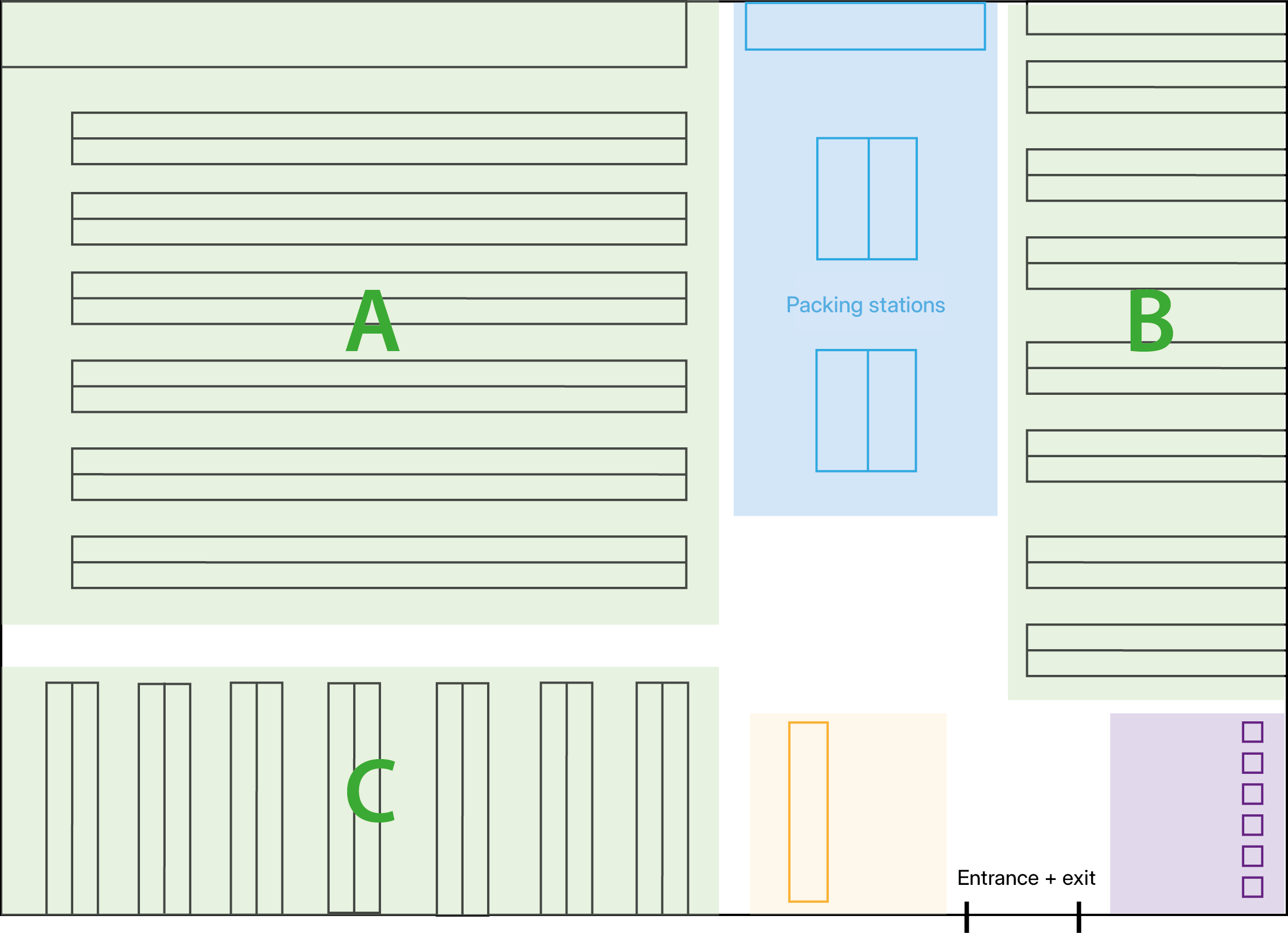

If you only have one entry/exit, we recommend creating a receiving and dispatch area on either side of the door. This keeps full roll containers out of the way and provides a clear location for incoming goods. The example below illustrates this approach.

Locate packing stations centrally

Pickers spend 60–80% of their time walking around the warehouse. By designing your warehouse efficiently, you can save a lot of time by reducing walking. One way to do this is to place packing stations in a central location, such as the middle of your warehouse.

Arrange your aisles so they connect the entrances to the packing stations, making it easier for pickers to reach the pick locations.

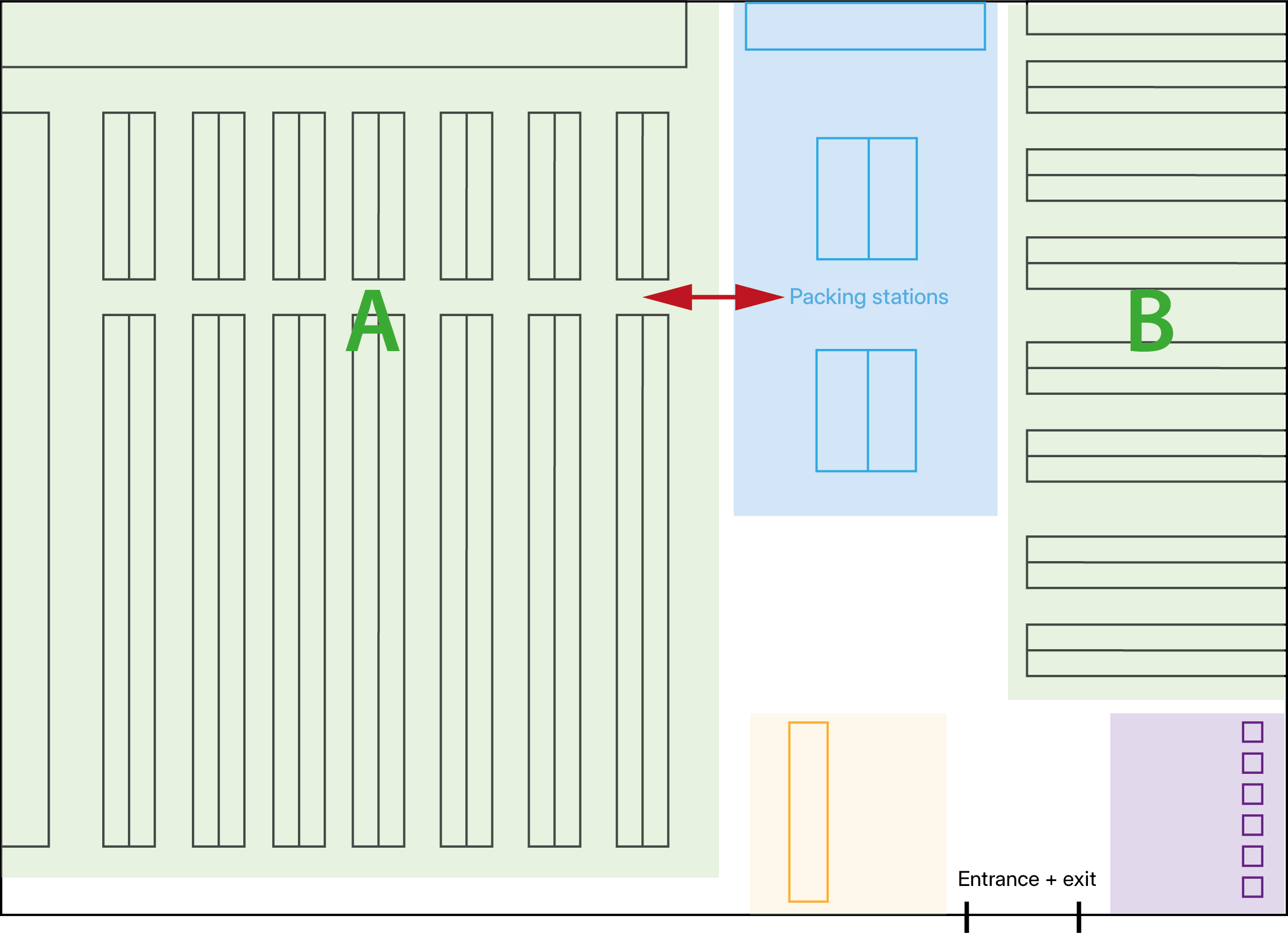

It might not be possible to place racks horizontally like in the example due to limited walking space. In that case, see if you can create a central entrance. This still allows easy access to the warehouse from the packing tables, with left or right options.

Adequate space between aisles

To avoid collisions, it’s important to leave enough space between aisles and between packing tables and aisles. This ensures smooth movement even during busy periods, while still allowing easy transport of products to and from the packing tables.

Many warehouse owners first consider how many racks they can fit and then worry about space. We recommend doing the opposite. The calmness of extra space often outweighs the benefit of an extra rack. Warehouses with more space tend to feel bigger, making picking more comfortable.

Other flows

Besides people walking with products, many other objects move around constantly, such as boxes and roll containers. By assigning fixed locations, everyone knows where to get and return these items, maintaining clear oversight.

It’s helpful to always keep roll containers in the same place. Place an empty container next to the packing table so the order can go directly in after packing. When full, move it to the roll container station near the warehouse exit for easy handoff to carriers.

Consider having a dedicated rack with supplies for the packing table, located as close as possible to minimize time spent replenishing.

Keep fast-moving items close

Your best-selling products are your fast movers. Place these as close as possible to the packing tables, for example at the start of an aisle. This reduces the distance pickers need to travel. Using the ABC analysis in Picqer, you can quickly identify your most frequently picked items.

Choose the right location

Decide which location suits each product best by considering its size and expected sales volume.

It may be tempting to organize your warehouse by brand or product type. This can become a problem when locations run out. You’ll have to move products around to make room for certain brands. By choosing locations based on product specifications like size and turnover, you avoid this.

Picqer lets you assign specific labels to locations, making it easy to distinguish for example, pallet locations. This way, you can assign a location to a product without walking into the warehouse to check the space.

Have clear location signage

If you organize by location rather than product, it’s especially important to make them easy to find. Think of IKEA’s self-service warehouse, where clear signage makes finding products effortless. Aim to make your warehouse just as navigable. Number each zone with a letter, clearly mark aisles, and give each rack and shelf its own number.

Divide your warehouse into zones

As mentioned, you can split your warehouse into zones. This could be a group of racks, a floor, or a product type. For example, a zone of smaller racks could hold only small products.

Assigning a letter to each zone makes it easy to remember. New employees can quickly learn that zone A is on the left and zone B on the right. Zones also help you quickly decide where new products should go. You can even assign a product to zone B right at receiving.

Use batches

If you process more than 100 orders a day, working in batches is useful. A batch allows you to pick multiple orders at once. Depending on product size, you can pick 4–20 picklists simultaneously.

The image above shows a batch pick route, allowing you to cover multiple zones at once and then pack the picked orders sequentially at the packing table.

We often see that 60–70% of webshop orders contain only one line item. Picqer has a unique feature for this: single batches. This lets you collect all orders with only one product at once.

Always place products at the best spot

It’s worth reviewing your warehouse layout periodically, especially if your product range changes seasonally. You can plan a new layout at the end of the season when your warehouse has the most empty spots.

You don’t need a major overhaul every season. You can also print a monthly list of the top 20 best-selling products to check if they are still in the optimal spot. A previously slow-selling product might now be a fast mover, which you’ll want closer to the packing tables. You can adjust this during normal operations, so the warehouse doesn’t need to stop for hours or a full day.

Get started today

Do you want to optimize your warehouse layout? Discover which tips from this article you can put into practice.

For example, draw a scaled floor plan of your warehouse and cut out the racks and packing tables on separate paper. Now you have a puzzle of your warehouse and can experiment with different layouts.

Want more tips to optimize your warehouse? Our free whitepaper is packed with practical advice.