How to use location numbers in your warehouse

We often say it: use location numbers in your warehouse. You might think, “I don’t need them, I know where everything is because I’ve organized by brand or product category.”

But when we walk through e-commerce warehouses, we often see how difficult it is to get started picking orders without location numbers. You either need to search for products or memorize where everything is.

By assigning a unique number to every location, you can work much more efficiently. You don’t need to remember where products are, because you pick based on numbers rather than product knowledge. When using warehouse software like Picqer, your picklist shows exactly where to go. This means new employees can start picking quickly, you can process multiple orders at once, and your warehouse layout becomes more flexible.

In the video, Wahid explains how to use location numbers in your warehouse. We’ve also included a full breakdown and extra tips below.

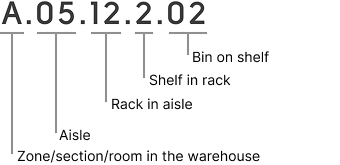

How do location numbers work?

A location number is a combination of letters and numbers that points to a specific spot in your warehouse. Each zone, aisle, rack, shelf, and bin gets its own identifier. Based on the location number, you always know where a product is stored.

The structure above works well for most e-commerce warehouses. It’s clear both on a macro level (direction, zone and aisle) and micro level (exact product, rack, shelf, and bin).

You can adjust the structure if your setup is different. If you don’t use zones or shelves, skip those levels. If you store items on the floor instead of in racks, you might use something like A.05.12 as your ground-level location.

Don’t have time to label your entire warehouse? Start small. Begin with numbering your zones, aisles, and racks — that takes about a day. This already helps pickers find the general area. Better to start with a partial system now than wait six months to label everything at once.

Extra tips for numbering

- Number aisles instead of individual rack rows.

- Use even and odd numbers like house numbers: odd numbers on the right, even on the left. This creates a logical walk route when you sort locations in Excel.

- Use leading zeros to make every part of the number equally long, like “05” for aisle 5. It’s easier for the brain to scan.

- Separate parts of the number with dots or dashes, like 03.05 or 03-05, instead of 0305.

- Ideally, store only one unique product per location for maximum efficiency.

What can you do with location numbers?

- New employees can start picking right away. Hand them a picklist with location numbers and they’ll know exactly where to go.

- Pickers don’t need product knowledge or memory to find items.

- You can easily move or add products. Place it in an available location, enter the location number, and you’re done. Pickers will see the update without needing to relearn the layout.

- Picking becomes nearly error-proof because items are picked by location, not appearance.

- Picklists can be automatically sorted in an optimal route through your warehouse.

- Multiple orders can be combined in one batch, grouped by proximity of items.

Examples

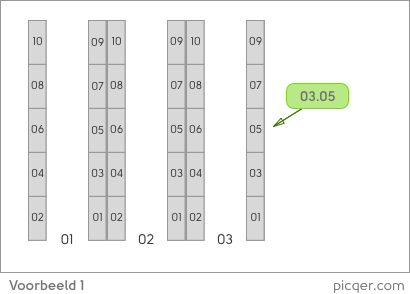

Below is a top-down view of a simple warehouse. Each gray block is a rack. No zone letter is used, since there’s only one room. Three aisles are labeled, with odd numbers on the right and even numbers on the left. The location number is: 03.05.

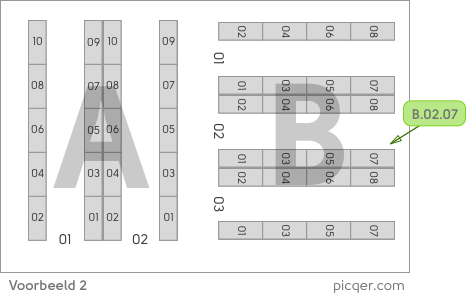

The next example is also one room but with multiple layout sections. These sections are treated as separate zones with their own letters. Aisles can be numbered per zone or continuously. The location number is: B.02.07.

In the final example, you see a front view of two racks: B.02.05 and B.02.07. Shelves are numbered bottom to top. You can divide shelves into as many bins as needed. We’re now at shelf 3, bin 03. The full location number is: B.02.05.3.03.

Make all physical locations clearly visible

When your warehouse locations are also visibly labeled, pickers don’t have to waste time searching. Don’t just label aisles and racks — label every shelf and bin. Make sure aisle numbers are still visible when walking through them. You can mark ground locations with paint or tape. Use magnetic shelf labels so they’re easy to move later.

Always show the full location number on every label, because that’s what appears in the software and on picklists. It also makes it easier to confirm you're in the right spot. For example, a rack should be labeled A.05.12 instead of just 12, and a bin should say A.05.12.2.02 instead of just 2.02.

How it works in Picqer

Using location numbers in Picqer can save you a lot of time. The Locations feature helps you streamline your processes. You can see which products are in which locations at a glance. Picqer also automatically sorts your picklists in the most efficient route. You can even pick multiple orders at once in a batch, based on nearby products — here’s how batch picking works. You can also print location numbers directly on labels. And if you use barcode scanners, just scan the location — no need to enter it manually.