Go-in-Style.nl: Getting a little better every day in the warehouse

We visited Picqer user Go-in-style.nl, a webshop specializing in truck styling parts. Due to their growth, they recently moved to a larger warehouse. Since then, they’ve been using Picqer. I spoke with Jesse Bergshoeff, shop manager at Go-in-style.nl.

Jesse shared how they set up Picqer before the move to ensure maximum efficiency in the new warehouse, and what they do to keep getting a little better every day.

Setting up Picqer

The move to a new warehouse was the perfect time for Go-in-style.nl to start using warehouse software. Jesse worked together with external partner Marloes Hees from Yuccaa to implement Picqer.

All products were measured and weighed so the data would be accurate, allowing them to automate based on that data. They also did a full stock count, since the stock in Picqer needs to be the source of truth. New locations were added, barcodes were assigned to products, and everything was labeled with stickers.

They completed this setup a few weeks before the actual move, so data could already begin to build up. Orders were already being processed through Picqer, giving them insight into their top sellers. Based on the ABC analysis, they organized the new warehouse and gave every product a logical location.

Alternative product photos for warehouse staff

On the Go-in-style.nl webshop, most product images show the item already mounted on a truck. This makes it hard for order pickers to identify the right item during picking. That’s why they’ve added alternative product photos in Picqer. Pickers only see the standalone image of the product they need to pick. This helps speed up the process and reduces mistakes.

Automatically snoozing large packages

Packages longer than 1.8 meters follow a different logistics process. They are usually shipped with TNT or XXL parcel services. These shipments are batched and processed on Tuesdays and Thursdays. They use tags and rules to automatically snooze picklists until then.

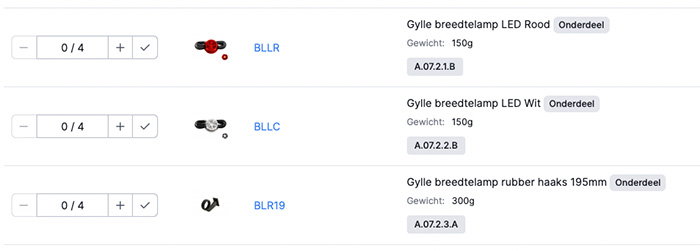

Bundled products

They also use a lot of bundled products. One example Jesse gave is a lamp, which consists of a rubber part, a front, and a back. On the webshop, it appears as a single, assembled product. But in the warehouse, it’s stored as three separate products in different locations. During the pick route, the picker grabs all three components, which are then combined into a single product.

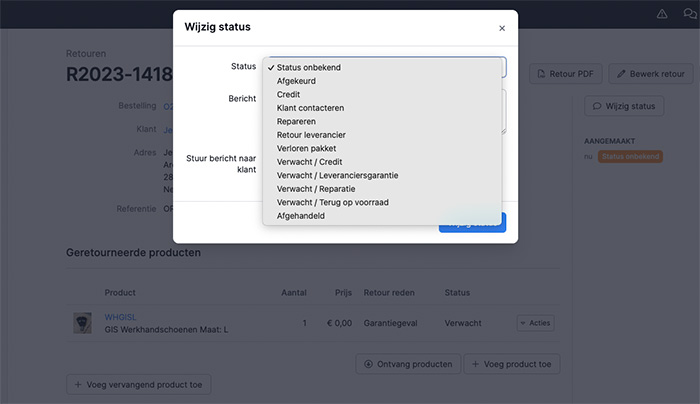

Processing returns with Belco

For handling returns, they use the integration with Belco. When a customer calls Go-in-style.nl’s customer service, Belco automatically shows the customer’s details. The phone number is recognized, and order info is pulled from Lightspeed. In Belco, they can instantly create a return, which then appears in Picqer.

To manage returns clearly, they’ve created several tags—like expected/credit. When the item is received in the warehouse, the tag is changed to credit, and the return is automatically passed on to the admin team for processing.

Getting a little better every day in the warehouse

At Go-in-style.nl, continuous improvement is a priority. Each day starts with a morning briefing. During this meeting, they review staffing, scheduled pickups, expected deliveries, and other warehouse updates.

They’ve also introduced a meeting structure with separate warehouse and office meetings. These result in actionable decisions, and the whole company is involved.

Several concrete improvements have already come out of these meetings. For example, they realized it didn’t make sense to include bulk stock on picklists. They switched to putting bulk stock on backorder and started using Picqer’s refill advice to replenish picking stock on time.

Another improvement came from a simple observation: one tag color looked too similar to DPD’s red. They changed the color to improve visual clarity—problem solved.

They’ve also documented all their workflows. For example: how do you process a return? How do you create one? This reduces dependency on any one person. Everyone knows where to find the information and can carry out the process independently.

Want to hear the full Go-in-style.nl story? Watch the video here.