New integration: Innosend

You can now connect Innosend to Picqer. Innosend is shipping software that makes it easy to send packages worldwide. With this integration, you can print shipping labels directly from within your warehouse software.

What is Innosend?

Innosend is user-friendly shipping software designed for all kinds of webshops. You can ship parcels using multiple carriers, so you always get the best shipping rate. Smart shipping rules automatically match orders to the right carrier. With Innosend, your shipping process becomes much simpler and more streamlined. They’ll even help you set up your account for free, so you can get started right away.

What can you do with the integration?

- Print shipping labels directly from Picqer with one click.

- Thanks to smart shipping rules, the correct labels are automatically applied to the right orders. No technical knowledge required.

- Send Track & Trace emails to keep customers informed about their deliveries.

- Accepting and processing returns is quick and easy with the return software.

- Both the tracking and return portals can be customized to match your branding.

Connecting Innosend to Picqer

You can set up the integration directly from your Innosend account. Create a free account, or get in touch with Innosend if you’d like help setting it up at no cost.

Eliminate the know-it-all

We say it often: eliminate the know-it-all in your warehouse. But why do we say this, and who exactly is the know-it-all?

In every warehouse, there is that one person who knows everything and can do everything. The person everyone turns to first when they have a question. Maybe that person is you, or maybe it's a colleague who has worked in the warehouse for years.

Where are the fragile-item boxes stored? How does the label printer work? Where should I place the parcels for the bike courier? How do I fill in a customs form? As soon as someone doesn’t know the answer, the process slows down. Luckily, there’s the know-it-all. You rely on them.

And that’s exactly the problem. The work becomes slower, more complicated, and more mistakes are made. As a result, the warehouse feels chaotic. If the know-it-all goes on vacation or calls in sick, or if your webshop is growing and you need to onboard new staff quickly, it’s a problem when vital information lives only in one person’s head.

That’s why we say, eliminate the know-it-all. Make sure everyone knows how processes work, how to use tools, and where everything is. The simpler you make it, the more independently everyone can work. Here are 4 tips:

- Keep processes and tools (both hardware and software) simple.

- Document every process and hang it somewhere visible, so everyone can see the steps and responsibilities.

- Make sure everyone has the same knowledge. Avoid exceptions.

- Keep everyone informed about changes.

This helps your warehouse run smoothly and feel more calm, because everyone knows what to do. Busy times or staff shortages can be handled more flexibly. A colleague from customer service or marketing helping out for a morning isn’t just convenient and fun, it also gives them a better understanding of warehouse operations.

If you’re the know-it-all, this might not sound appealing at first. But with fewer simple, repetitive questions, you’ll have more time to put your valuable knowledge to better use. For example, by creating a strong onboarding checklist or mapping out improvements for the entire warehouse.

This way, you go from one know-it-all to a strong team where everyone knows what’s going on.

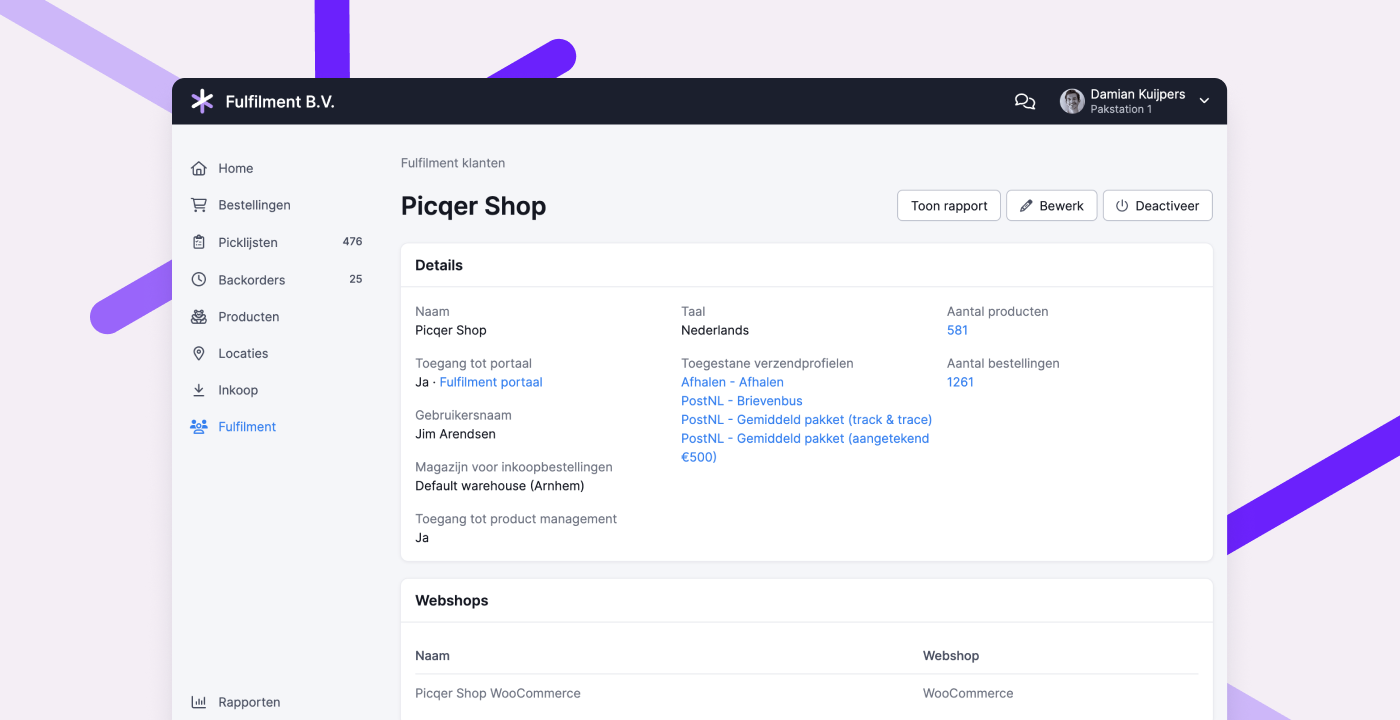

Changelog: Fulfillment improvements and other updates

This month, we’ve made several improvements for fulfillment companies. We’ve summarized these and all other updates in Picqer in this changelog.

Improvements for fulfillment companies

- You can now set a preferred warehouse per fulfillment client for purchase orders placed through the fulfillment portal. This prevents stock from being received in the wrong warehouse by mistake.

- When deactivating a warehouse, any linked fulfillment clients and webshops are now automatically unlinked. This saves you the work of doing it manually.

- In overviews, filters, and on detail pages, it’s now clearly indicated when a fulfillment client is inactive, so there’s no confusion.

- On a fulfillment client’s page, you can click directly to view and edit the allowed shipping profiles. This makes it easier to manage them.

- When exporting purchase orders, you can now filter by fulfillment client.

- In the fulfillment client report, the number of shipments is now based on the shipments created during the selected period, rather than those created for picklists processed in that period. This gives a clearer picture of the actual actions performed per fulfillment client.

Other improvements

- If you're linked to a packing station, you'll now see that under your name at the top of the screen. When creating a shipment, you’ll also see the selected packing station and can change it if needed. This helps prevent labels and packing slips from being printed at the wrong station when working across multiple stations.

- For returns, you can now see which products are inactive. These products can no longer be returned to stock, helping prevent “phantom inventory.”

- The

order.status_changedwebhook is now triggered when the order status in the webshop changes from “expected” to “concept” or “processing.” - We’ve added a new API endpoint to retrieve all outstanding purchase orders for a product.

- If you're using multiple warehouses, the warehouses overview now shows the total stock value of all warehouses combined.

- You can now disable ABC classification and use the products API endpoint to classify products yourself. This allows you to apply your own algorithm for classification.

New integration: Order2Flow

You can now connect Order2Flow to Picqer. Order2Flow links all your sales channels, inventory system, and accounting software to Picqer. This automates your entire order processing flow, so you can handle orders faster and more easily.

What is Order2Flow?

Order2Flow (developed by Pazion) is a modular order platform for e-commerce businesses. It connects different types of software, such as your webshop, marketplaces, ERP and accounting tools, fulfillment services, dropshipping partners, and shipping carriers. This makes the entire order flow transparent and manageable.

By connecting these systems, your software works together more efficiently, and essential data is kept in sync. As a user, you get a clear overview of everything from pending orders to revenue, all in one intuitive dashboard.

Order2Flow also offers custom configurations in addition to their standard base application, tailored to your specific needs.

What can you do with the integration?

- Order2Flow links your sales channels, inventory system, and accounting software to Picqer.

- It automates your entire order process, helping you process orders faster and with fewer errors.

- Data is synced one-to-one between connected systems.

- You get a clear overview of all relevant information in an easy-to-use dashboard.

- Order2Flow supports standard Picqer integrations for platforms like Amazon Marketplace, Mirakl, Reeleezee, OpenCart, and more. If you use other software with an API, custom integrations are possible upon request.

Connecting Order2Flow to Picqer

Order2Flow handles the connection with Picqer for you. On order2flow.io, you can see which integrations are already supported. If you're using other software with an API, you can contact Order2Flow to discuss your options.

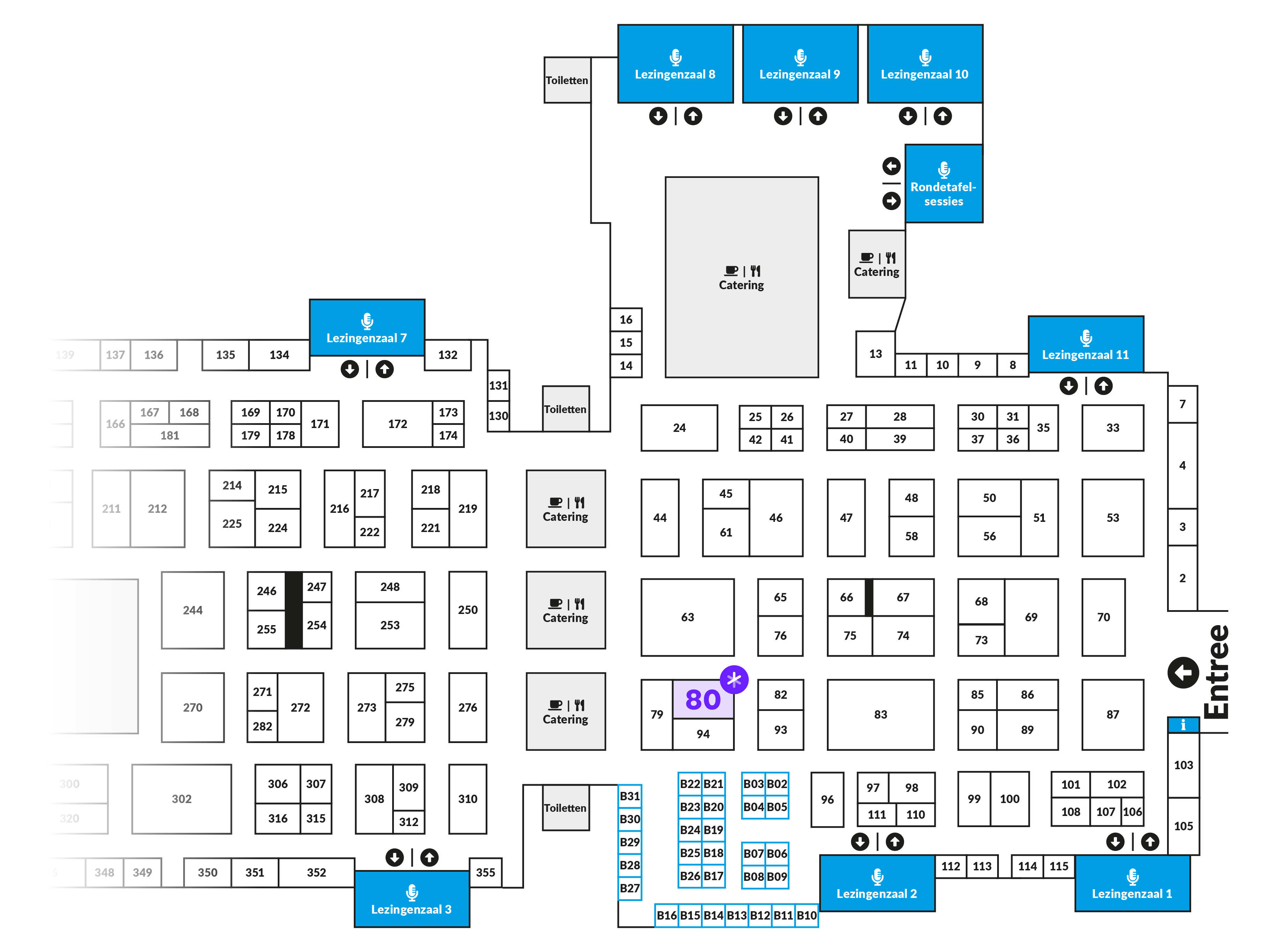

Picqer at the Webwinkel Vakdagen 2024

The Webwinkel Vakdagen takes place on Tuesday, January 23 and Wednesday, January 24 at the Jaarbeurs in Utrecht. And we’ll be there again.

The Webwinkel Vakdagen is the go-to event where e-commerce professionals come together to share knowledge and discover the latest trends. It’s also the perfect opportunity to get inspired about how to optimize your warehouse.

Stop by for advice or a chat

Come visit us at our stand and talk to one of our team members about warehouse optimization. We’re excited to meet you and have a chat. You’ll find us at stand 80.