Changelog: New conditions and actions for rules, and more updates

In recent weeks, we’ve introduced several improvements for date and time-based rules. Read more about these and other updates in this changelog.

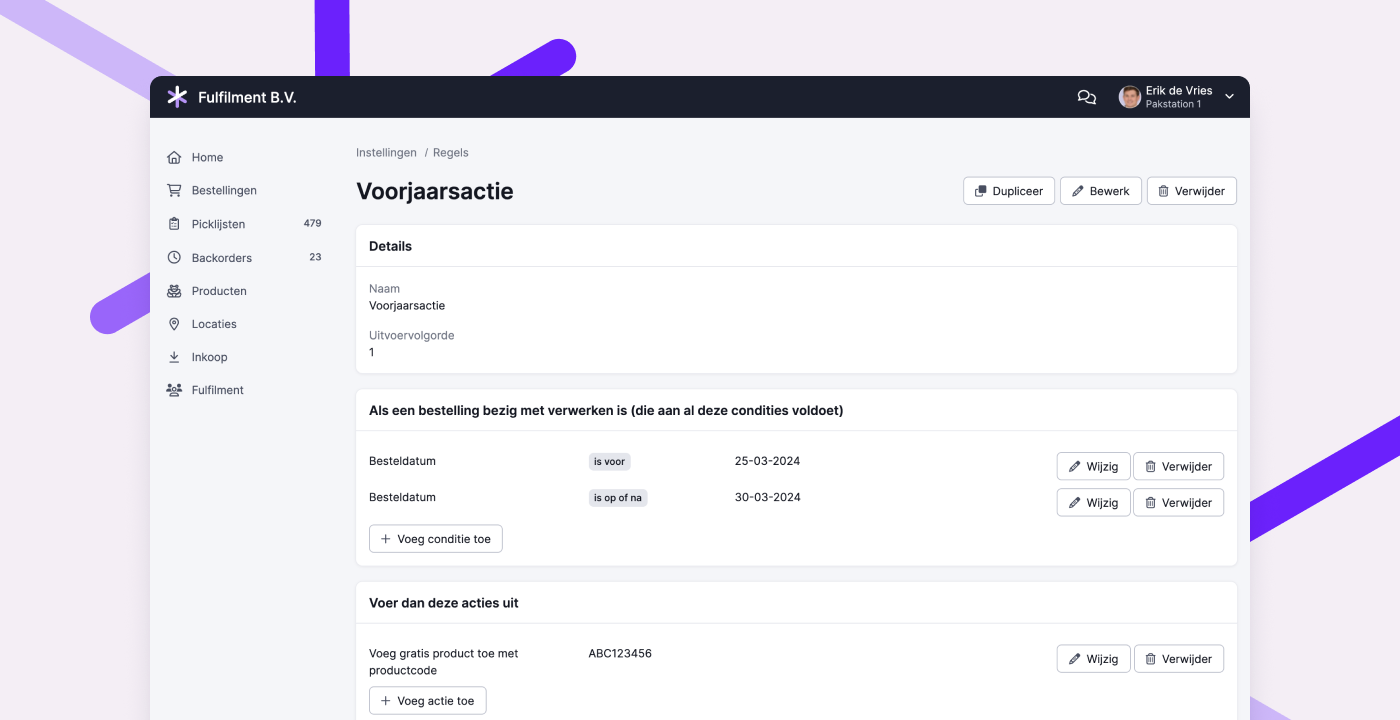

Conditions based on order date and time

You can now set specific order dates or times as rule conditions. For both, you can choose from two options:

- The order was placed before the date or time

- The order was placed on or after the date or time

You can combine multiple conditions to trigger actions during a specific time frame. For example, you could offer a free gift for orders placed during a promotional period, or apply a different shipping method depending on the time an order was placed.

Snooze picklists for a set number of hours or until a specific date

When snoozing a picklist using a rule, you can now specify how many hours it should be snoozed. You can also set a specific date to resume the picklist. This is especially useful for pre-orders that should only ship on or after the product release date.

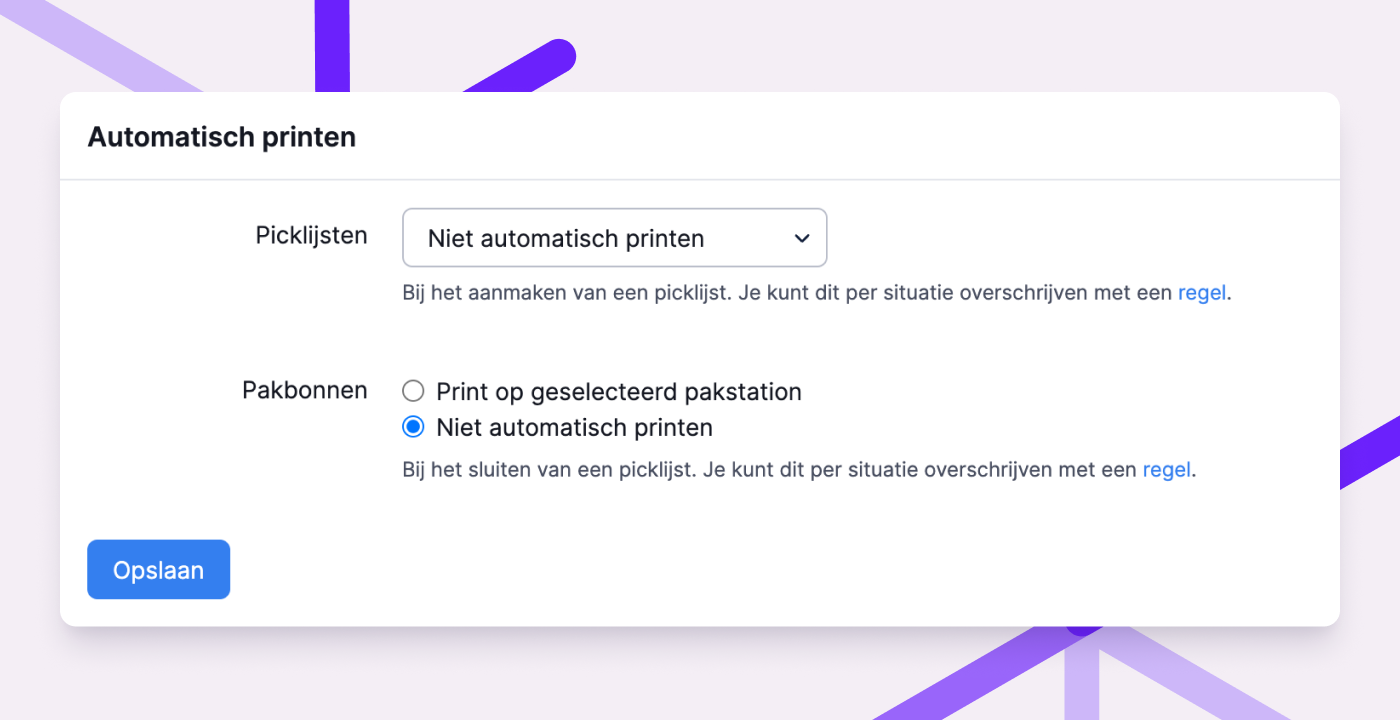

More control over printing packing slips

Previously, packing slips were always printed automatically if a packing slip printer was set up at the packing station. You can now decide whether to print packing slips at all. Using rules, you can override that default setting. This gives you full control and can save a lot of unnecessary paper.

Read more in the help article on printers and packing stations.

Other improvements

- Processing orders with many backorders and/or product compositions is now much faster.

- In the popup for creating a shipment, you now clearly see which shipping profile was preselected via a rule.

- We’ve added a new integration with Sendy.

- You can now quickly recognize which orders were placed via the fulfillment portal with a dedicated icon in the order overview.

- The shipping method “Small Parcel” from PostNL has been added to the MyParcel integration.

- When you turn a product into a virtual composition or mark it as having infinite stock, the ABC classification is removed.

- The graph on the customer page showing order history now always displays accurate data.

- A warning is shown if you try to leave a rule setup page without saving your changes.

- We now import QLS service points for orders from Shopify and Lightspeed, so the information is automatically passed to the carrier.

- When creating a purchase order via the API, you can now include a

delivery_date. - The track & trace URL for shipments to Belgian pickup points now works correctly again.

- The customer and supplier pages have been redesigned for improved organization and consistency with the rest of Picqer.

- The normal and singles batch pages have been updated for users who have enabled the experimental feature “Updated picklist and batch pages.”

New integration: Sendy

You can now connect Sendy to Picqer. Sendy is shipping software that helps you send orders quickly and easily. Orders are automatically converted into shipments, and the matching shipping labels are printed directly from Picqer.

What is Sendy?

Sendy’s shipping software makes your shipping process fast and simple. Orders are automatically converted into shipments with the carrier of your choice. The correct shipping labels are printed, and Track & Trace information is retrieved. Packed parcels can be picked up or dropped off at a nearby pickup point. Any customer questions about the shipment can easily be answered using the software.

What can you do with the integration?

- View all orders and their shipping status in one system.

- Use rules in Picqer to apply the correct shipping profiles.

- Orders are automatically converted into shipments with the matching label, which is printed directly from Picqer.

- Track & Trace information is automatically synced back.

- Answer customer questions about delivery directly in the software using Mijn vraag.

How to connect Sendy and Picqer

You don’t need any technical knowledge to set up the connection. Start by creating a free Sendy account, then connect Picqer from within your Sendy account. The step-by-step instructions are in our help article. Want to know which carriers and rates are available through Sendy? You can find that here.

New to the team: Ruud & Leonie

We’ve welcomed two new colleagues to our team! In February, Ruud (development) and Leonie (support) joined Picqer. They’re excited to introduce themselves:

Ruud Schuurmans

Hi! My name is Ruud, and on February 1st I started at Picqer as Head of Engineering. In this role, I get to coach the engineering team and help ensure we continue building the very best warehouse software out there. I also help keep an overview and translate company goals into (technical) objectives for the engineering team.

From my previous roles, I bring a background in software architecture, which is all about logically structuring and organizing the code behind software. I’m excited to bring that experience into Picqer and help the team work with clear and understandable code. The ultimate goal is a well-aligned team that can develop new Picqer features with ease, speed, and pride.

I’m originally from the Achterhoek, but for quite a few years now I’ve lived in Arnhem, close to the city center. In my free time, I enjoy grabbing a coffee in town, taking a walk through Sonsbeek Park, or heading out for dinner.

I’m really looking forward to helping the Picqer engineering team build even better software for our users!

Leonie Smit

Hi, I’m Leonie, and since February 1st I’ve been working at Picqer as a Support Specialist. Before this, I worked in customer service for a furniture webshop. There, I was also involved in optimizing the processes behind the scenes. I’ll now be helping my new colleagues deliver the best support, so we can make Picqer even better!

In that previous role, I came across Picqer for the first time. As a customer, I reached out to Picqer’s support team—and had such a positive experience that it led me here. The great software, friendly team, and calm atmosphere made Picqer the perfect place for me.

I live with my elderly cat Bibi in the oldest city in the Netherlands: Nijmegen. Outside of work, I love reading (mostly fiction), gardening, and going on walks. With spring around the corner, I’m looking forward to getting the garden back in shape! And now that the new Formula 1 season has started, you’ll often find me spending my weekends (shouting) at the TV.

I’m excited to dive deeper into Picqer and contribute to providing the very best support!

Reducing errors in your warehouse

The moment a customer receives their order can make or break their experience. Sending the wrong quantity, the incorrect size, or delivering later than promised increases pressure on your customer service team and might even prevent that customer from returning.

That’s why it’s essential to make as few mistakes as possible in your warehouse. Not only to meet your promises consistently, but also because fixing a mistake costs time and money.

But how do you improve when every day is already packed? Investigating the root cause of mistakes takes time. Still, if you take the time this week to fix one issue, you’ll likely benefit from it as soon as next week. And that improvement compounds over time.

Below are two real-world warehouse examples to inspire you. What problems did they encounter, how did they solve them, and what results did they see?

Example 1

Context: a webshop with a small collection of printed t-shirts, handling about 30 orders per day. They wanted to reduce mistakes but weren’t yet large enough to invest in warehouse software.

All sizes from a single collection were stored in the same rack. Since the shirts looked nearly identical across sizes, the wrong size was often picked and shipped.

Staff decided to reorganize the warehouse by grouping by size rather than collection. Now, all sizes are separated by rack, so it's easier to find the right shirt with the art print in rack M than to search among eight similar-looking sizes in one location.

Example 2

Context: a large webshop with a varied product range, about 1,000 orders per day, and 3 full-time receiving employees. Incoming products were piling up, making it hard to deliver on the promise: “Not in stock? Shipped within 5 days.”

The receiving team started tracking how long it took for products to become pickable after arriving. The result: an average of 5 days, with some taking as long as 20 days. Because of these outliers, the 5-day promise couldn’t be guaranteed. Customer service began prioritizing specific orders, which in turn delayed others.

Instead of disabling backorders or extending the 5-day promise, they held an improvement session to identify the real issue. They discovered that employees prioritized easy items, while bulkier products were left untouched longer due to the extra work required.

The solution: a whiteboard with three columns—“to do,” “busy,” and “done.” For each incoming delivery, a post-it was created with key info such as the delivery date. Notes were added in order of arrival. When a team member started processing a delivery, they moved the post-it to “busy” and added their name, so everyone knew who was working on what.

Three months later, they measured again. The average processing time dropped to 1.3 days, with a maximum of 2 days. A huge improvement, especially considering such a simple system created so much impact.

This new method didn’t just bring more structure to the warehouse, it also eased the pressure on customer service and made it possible to confidently promise a 5-day turnaround.

These examples show how small changes can lead to big improvements. Feeling inspired? Here are some tips to get into improvement mode:

- Schedule regular improvement sessions with your team. Discuss where most mistakes occur and investigate the root causes. Create a list of issues and pick two pain points to improve, so you’re already doing better next week.

- Look for ways to eliminate exceptions from your process. Don’t only consider the downsides—such as “we’ll lose 5 orders per week if customers can’t pick up”—but also the upsides: “fewer mistakes are made when we stick to a consistent process.”

- Don’t rely solely on external benchmarks. Use your own data to track weekly progress and see where you’re improving. Try things out. Which tweaks positively impact your performance?

- We regularly share tips and inspiration on our blog and in our Help Center. Take advantage of it!

Changelog: Rule improvements and other updates

Over the past month, we’ve introduced several improvements to how rules work in Picqer. These updates give you more control and clarity. Here’s an overview of all changes.

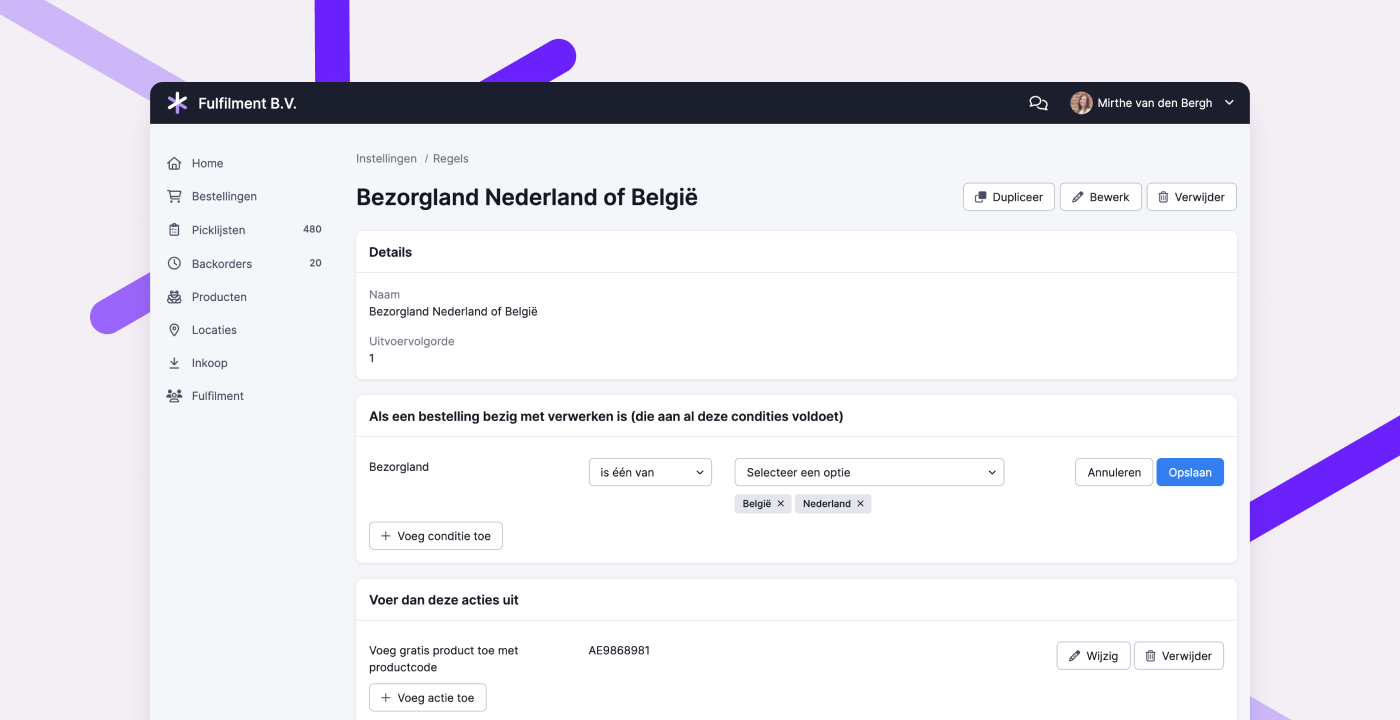

Select multiple shipping countries and fulfillment clients

When a rule applies to multiple shipping countries or fulfillment clients, you can now use the condition “is one of” or “is not one of.” You can then select one or more countries or clients. This helps reduce the number of separate rules you need, making things easier to manage.

Edit rule conditions and actions

You can now edit existing conditions and actions in a rule. This makes it much easier to apply updates, like adding an extra fulfillment client or shipping country to an existing rule.

Filter rules by fulfillment client

In the full list of rules, you can now filter by fulfillment client. This makes it easy to see which rules are active for each client.

On the fulfillment client detail page, you’ll now see how many rules are linked to that client. Clicking the number shows you exactly which rules they are.

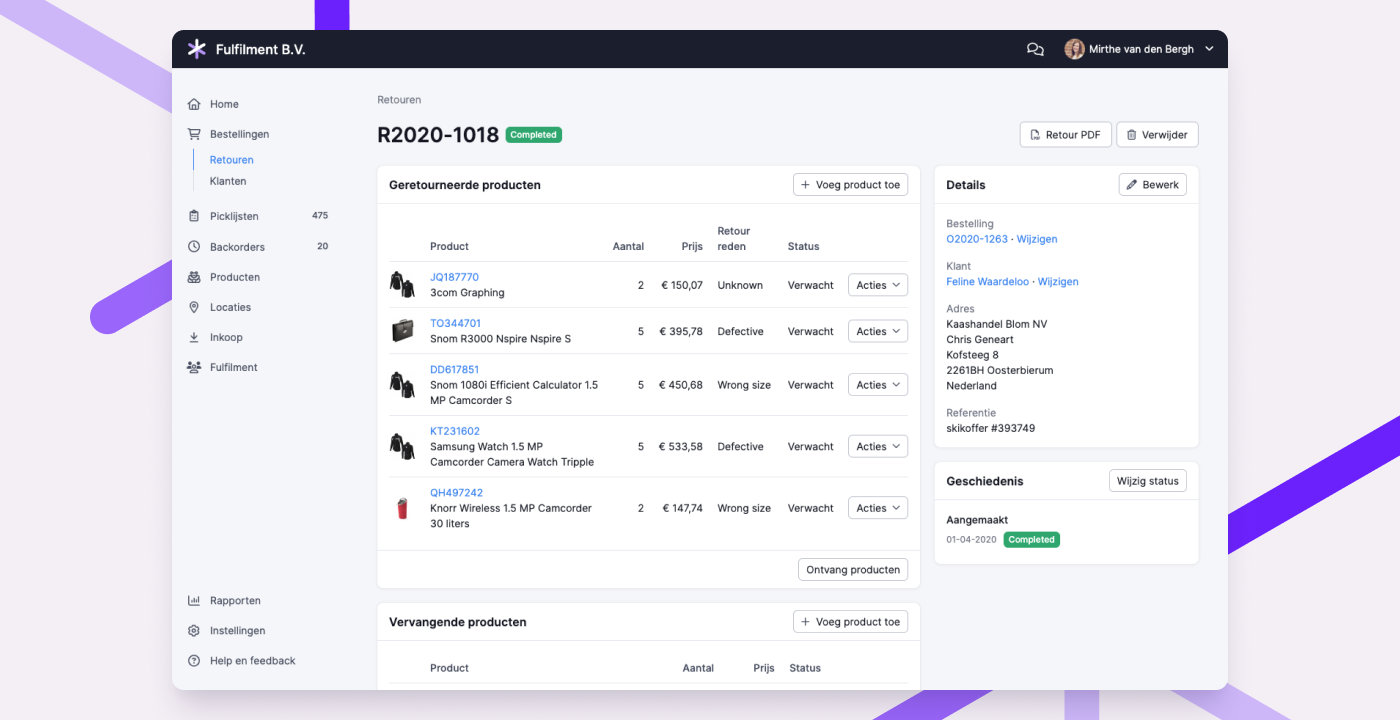

Updated return page design

We’ve refreshed the design of the return page. This is part of a larger effort to make the entire Picqer interface more organized and consistent.

When pages follow the same structure and layout, it’s easier to find the information and actions you need. It also helps new team members learn the system faster.

Still using the old menu, picklist or product page? Try out the new versions via Experimental features.

Other improvements

- When using the Sendcloud integration, you can now choose which contract to use in Picqer if you have multiple contracts with the same carrier in Sendcloud.

- The purchase order export now includes the warehouse, number of products, and expected delivery date.

- When importing stock, locations labeled as “Container” are now excluded, so stock can only be imported into fixed locations.

- In the fulfillment report, shipment statistics per profile and country now include the selected date instead of ending just before it.

- The Excel export of a purchase order now includes product barcodes in the final column.

- We added the

closed-picklists-todayendpoint to the API stats endpoint. This shows how many picklists have been closed today. - We also added the

idpicklist_batchattribute to the picklist endpoint, so you can see which batch each picklist belongs to.