New logo for Picqer

After 11 years, it’s time for a new logo and a fresh visual style for Picqer. One that tells our story. One that shows we simply build great warehouse software, while staying personally involved with our customers. Last year, we partnered with Verve to make it happen.

The logo

Together with Verve, we created our new logo. We’re moving from blue to purple. From cautious to confident. And from a pallet with a cloud to the Picqer Link.

The grid

Multiple links form a grid. This grid is inspired by warehouse shelving. It represents structure and leaves room for growth. That’s what we do for webshops. We bring structure to the warehouse and create space to grow.

Inspiration and the grid

The grid and different versions of the Link are key elements you’ll start seeing everywhere.

Purple

Now about the color. Our old blue logo felt too corporate. We’re deeply engaged with our customers. We want to understand them and help them as best we can. That calls for a warm, human color. That’s purple. Picqer Purple.

We’re super excited about our new look. In three weeks, you’ll see it on full display at the Webwinkel Vakdagen.

Changelog: Improved fulfillment reporting and other updates

Over the past few weeks, we’ve made several updates for fulfillment companies. The dashboard has been redesigned, and the reports have been expanded and made exportable. This makes invoicing and related communication much easier. You’ll find a summary of these and other improvements in this changelog.

Redesigned fulfillment client report

To provide a clear overview of the services provided to a fulfillment client, we’ve revamped the “Current Month Report.” The new report is easier to read and highlights key statistics. Each card links directly to a detailed overview. Reports are now exportable, making it simple to use the data for invoicing or administration.

This same report is now also available in the fulfillment portal. Your clients can view the services provided to them, so you don’t need to send this information manually. The detailed views, however, remain inaccessible to fulfillment clients.

Improved exports of processed picklists and shipments

The “Processed Picklists” and “Shipments” exports and reports have been expanded with new fields. For example, the shipment weight is now included in both reports.

Other improvements

- We added a new webhook:

products.created. This is triggered when a new product is created. Previously, you had to use theproducts.changedwebhook for this, but the new one provides a cleaner signal. - URLs in comments are once again properly detected and made clickable.

- We introduced a new API endpoint to close a purchase order.

- We added a new integration with Innosend.

- QLS service points are now imported with orders from WooCommerce and Magento 2, so the data is automatically passed on to the carrier.

- In the app, you can now assign a batch to yourself.

- We added support for 2 PostNL products:

- 4965 – Belgium Extra cover (EUR 500) + Deliver to stated address only

- 4878 – Pickup at PostNL location + Extra cover

- In some cases, products were missing from the replenishment advice. This issue has been resolved.

- When changing a product's purchase strategy to “Purchase only for backorders,” the “Replenish stock up to” value now automatically resets to 0, as does the reorder level.

New integration: QLS

You can now connect the QLS shipping service to Picqer. With QLS, you can ship parcels worldwide at a low rate. Shipping labels are retrieved in Picqer with a single click, and all created shipments are picked up by QLS at no extra cost.

What is QLS?

QLS is a logistics partner for webshops, offering fulfillment services, software, and a shipping platform. The QLS shipping service has a global network of carrier connections. This allows webshops to choose the right carrier based on speed, price, and destination. QLS picks up all shipments at no charge, and their network of logistics partners ensures timely delivery.

Both small and large webshops can benefit from QLS. Thanks to the daily volume of tens of thousands of parcels, QLS can offer low shipping rates and flexible options tailored to your webshop's needs.

What can you do with the integration?

- Retrieve QLS shipping labels in Picqer with a single click.

- QLS automatically shares Track & Trace details with Picqer. This information can be forwarded to customers so they can track their orders.

- Create shipping profiles and set delivery options to avoid manual settings for each order.

- All shipments created in Picqer are picked up by QLS free of charge.

Connecting QLS to Picqer

You can connect QLS as a shipping provider in your Picqer settings. Follow the steps here or visit the QLS integration page for more information.

How to use location numbers in your warehouse

We often say it: use location numbers in your warehouse. You might think, “I don’t need them, I know where everything is because I’ve organized by brand or product category.”

But when we walk through e-commerce warehouses, we often see how difficult it is to get started picking orders without location numbers. You either need to search for products or memorize where everything is.

By assigning a unique number to every location, you can work much more efficiently. You don’t need to remember where products are, because you pick based on numbers rather than product knowledge. When using warehouse software like Picqer, your picklist shows exactly where to go. This means new employees can start picking quickly, you can process multiple orders at once, and your warehouse layout becomes more flexible.

In the video, Wahid explains how to use location numbers in your warehouse. We’ve also included a full breakdown and extra tips below.

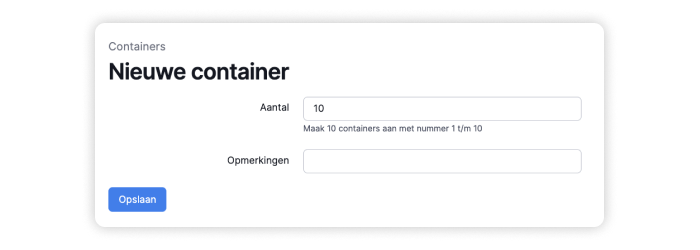

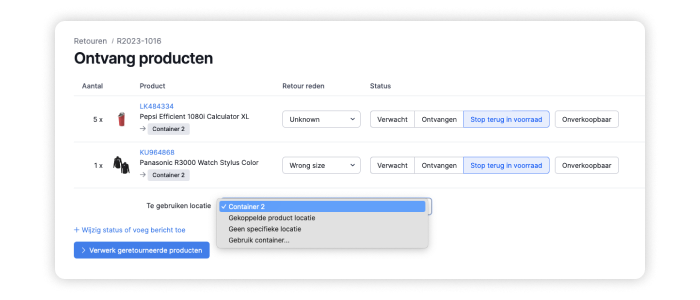

How to move products using Containers

Containers is a brand new feature that helps you track where your inventory is while moving products internally. It’s currently available when using replenishment advice, handling returns, and for manual stock transfers. In this post, we’ll walk you through how you can use Containers effectively in your warehouse.

A quick explanation of Containers

Moving products within your warehouse might take just one minute, or it might take several hours. During that time, your digital inventory in Picqer doesn’t match the physical reality. The products are no longer at the old location, but they haven’t yet arrived at the new one either.

With Containers, you can assign moved products to a “container.” This acts as a temporary location while you’re transferring items. That way, anyone in Picqer can see that the products aren’t at location A or B, but are currently in transit.

You choose how you move your products — using a cart, rolling rack, pallet, or even 100 small bins. In Picqer, you specify how many containers you have in your warehouse. You can also print barcode labels for your physical containers directly from Picqer.

Everyday use cases

Let’s say you want to move 50 items from bulk stock to your picking location using a rolling cart. By scanning the barcode on the cart as you move, you let Picqer know you're using that container for this transfer. You’ll now see in Picqer which products are in the container, sorted by pick location. When you reach the first pick location, scan the item as you take it out of the container. Picqer will then move it from the container to its new location.

You can also use Containers when processing returns. For example, say 10 different orders are returned on the same day. To work efficiently, you handle them all at once. At the packing table, you check whether each product can be restocked, then place them in the container. You bring the container into the warehouse, and one by one, scan and return the items to the correct locations.

While products are in a container, they’re counted as part of your stock, but they’re not available for picklists. Once you move them out of the container and into a fixed location, they immediately become available again. This lets you move products at your own pace without worrying about someone trying to pick them mid-transfer. It also means you don’t have to manually update the locations afterward.

Moving large volumes of products

Sometimes transfers take hours. Maybe you're moving two aisles of seasonal products to the back of the warehouse, or filling a new rack with stock. In these situations, a large quantity of products is without a fixed location for a while. Meanwhile, a colleague might be running a stock count or creating a picklist.

Using Containers for these kinds of bulk moves keeps everyone informed. Your colleagues can immediately see that the items are in a container and in transit from point A to B. This means everyone always has the correct stock information, no matter how long the transfer takes.

The better Picqer knows your inventory, the better it performs

From the moment a product enters your warehouse until it leaves, you want your inventory to be as accurate as possible. With Locations, you always know where your products are. And now, with Containers, you also know what’s currently on the move.

At this stage, you can use Containers with replenishment advice, returns, and manual stock transfers. We’re actively working on support for using Containers during receiving. Ultimately, we want every internal stock movement in your warehouse to be done via a container — because the better Picqer knows your inventory, the better it works.

We’ll keep you posted in future blog updates. Want to get started with Containers for replenishment or returns? Here’s how to create containers.