Move products to a new warehouse

Have you opened a new warehouse and do you want to move a lot of products to the new warehouse in 1 go? You can move products individually and assign them to locations, but you can also easily move them all at once. By following the steps in this article, the new warehouse will be created, the stock of moved products will be deducted from locations in the old warehouse, added to locations in the new warehouse, and the new warehouse will be ready for orders from your online store(s).

Steps to move your products in bulk:

1. Add a new warehouse

To create a new warehouse, click 'New warehouse' in the warehouse overview. For more details on adding a new warehouse, see our help page on Warehouses.

2. Add new locations in the new warehouse

You can create locations in the new warehouse in two ways:

A. Using the location wizard

The location wizard allows you to create many locations at once, making it easy to set up or expand your warehouse. Read more about this on our help page.

B. Using a location import

With a location import, you can bulk add locations to your warehouse using an Excel file. To perform a location import, go to Locations > Import/Export > Import locations. Make sure to select the newly created warehouse.

The Excel file should include the following columns:

- Name This is the name you assign to the location for identification.

- Parent This is the name of the parent location. For example, Location A is the parent location of A.1.

- Temporary location By default, a product remains linked to a location until you unlink it. For a temporary location, the link is automatically removed when the stock at that location reaches zero. Use 'TRUE' in this column if you want the location to be temporary. Use 'FALSE' to keep the location linked to a product.

- Bulk location If a location is a bulk location, its stock (depending on your general settings) is never used for picklists or is only used when stock at pick locations runs out. Use 'TRUE' to set the location as a bulk location. Use 'FALSE' if you do not want it set as a bulk location.

- Optional: Type To differentiate between types of locations, you can use location types. Learn more about this here.

3. Optional: Import new products

If you plan to store new products in the new warehouse, first import these products into Picqer. If you're only moving products from other warehouses, you can skip this step.

Import products in bulk into Picqer using a product import. Learn more about this on our help page.

4. Move stock from the old to the new warehouse

To move stock in Picqer from the old to the new warehouse, use Movements.

Using one location per product in the new warehouse?

First, link the products to a location in the new warehouse.

This can be done using a Product import. In the import file, specify the desired location of the product in the new warehouse under the column ‘Stock location Warehouse X’ (the name of the new warehouse).

All stock for the moved products will be placed at the specified location after completing the transfer.

Using multiple locations per product in the new warehouse?

Link the products to the new locations after the movement.

If no locations are linked to the moved products, the stock will be listed as 'No specific location' in the new warehouse after the movement. Use a Stock import to assign the stock to the desired locations.

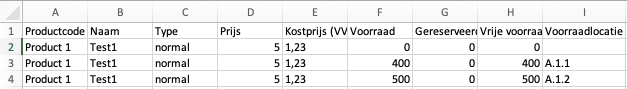

When linking two locations to your moved product, it looks like this:

Row two in the example ensures that stock at 'no specific location' is set to 0. Rows three and four assign the stock to the desired locations.

Move to the new warehouse

- In Picqer, go to Movements > New movement. Select the warehouses involved in the movement.

- Add the products to be moved. You can add them one by one or in bulk via an Excel file. If using an Excel file, ensure it includes the following columns:

- Product code

- Quantity

- Review the quantities in your movement and click 'Save'. Then, move all products at once by clicking 'Move all products'.

You can never move more stock than the current available stock. Stock reserved for picklists cannot be moved. If you want to move stock from open picklists, you must first cancel those picklists. Then update the warehouse in the related orders. Backorders created after canceling the picklists will now be assigned to the new warehouse.

Here's how you do this:

- Click on the picklist

- Cancel the picklist (More > Cancel)

- Go to the related order

- Click More > Revert to concept

- Click Edit in the details section

- Change the warehouse in the order to the new warehouse

- Save as draft, then process to create the new picklist.

5. Make the new warehouse available

Your new warehouse is now created, locations are linked to products, and the stock is in the right place. The final step is ensuring orders are fulfilled from your new warehouse.

For each store, specify which warehouses are allowed to fulfill orders. Open your Store settings and navigate to the relevant store.

- Under 'Fulfil from these warehouses' specify the warehouses to be used for orders from your online store(s).

- Under 'Warehouses for stock levels' ensure the correct warehouses are selected. Picqer only updates stock per store based on the warehouses selected here.

Helpful links