Recap: Picqer Warehouse Fest 2023

Last week, we welcomed Picqer users to Nijmegen for the Picqer Warehouse Fest—the successor to our annual Meet & Grill. Visitors came together to learn more about warehouse optimization and connect with fellow webshop owners.

Watch the aftermovie here:

Presentations

Casper Bakker kicked off the day with a look back at the past year and shared updates on the latest developments in Picqer. One of the highlights was the announcement of the new “Containers” feature, which will be available to all users next week.

Next up was Nick van Klinken from Alleeninkt.nl, who shared lessons from his 10 years as an e-commerce entrepreneur. His biggest takeaway? Talk to other entrepreneurs. A great introduction to the breakout sessions, which focused on bringing webshops together.

Breakout sessions

During the breakout program, attendees chose their own activities. There was plenty of knowledge sharing at the round tables on staffing, purchasing, and fulfilment. New connections were made during the speed dating sessions, and there was lots of interest in Picqer’s new features at the demo booths.

Networking drinks

We closed the day with live jazz music, drinks, and snacks at the networking reception. It was the perfect setting to exchange ideas and experiences.

It was a pleasure seeing everyone at the Picqer Warehouse Fest. We hope you made valuable new connections and left feeling inspired. See you next time!

Changelog: Comments in the app and other updates

Comments in the app

In addition to comments on pick lists, you can now view and add comments in the app for products, purchase orders, and receipts.

From the Dashboard, you can access the full comment overview. Just like on desktop, you can view all comments, only your own, or only the ones where you’ve been mentioned.

Comments on batches

You can now add comments to batches in both the app and desktop. These comments are also shown on the PDF version of the batch.

Comments on pick lists and orders are now separate

Pick lists now have their own dedicated comments. Previously, comments from the order were shown on the pick lists. With this update, comments for pick lists and orders are now separated.

Any comment you place on a pick list is only visible on that specific pick list. It no longer appears on the related order or on other pick lists from the same order.

Control comment visibility for orders

You can now choose whether or not a comment on an order should appear on its pick lists.

This is helpful when certain notes are only relevant to customer service, and not to the order picker. Conversely, comments meant for the picker can be shown on the pick list to help them stay focused while processing.

Other improvements

- For a product, you can now set the replenishment level of the pick stock even when using the purchase strategy “Only buy for backorders.”

- The order log now shows when a pick list is unsnoozed.

- WooCommerce orders that initially contained no products were previously marked as “ignored.” These now get the status “ignore until updated,” allowing them to be imported later once products are added.

- Searching in the “Order statuses” overview in the fulfilment package has been significantly sped up.

- We’ve added a new integration with QLS.

5 practical tips for your packing table

The packing table is a key part of the process from order to shipment. It’s where you prepare and pack all your orders for delivery. Since you repeat these tasks many times throughout the day, a fast and neatly packed parcel leads to happy customers. To work efficiently, it’s essential that your packing table is clean, comfortable, and easy to work at. In this blog, we share 5 practical tips for setting up your packing table so every package goes out perfectly.

Tip 1: Start with a solid and modular system

Choose a packing table that fits your product range and needs. Make sure you can choose from a wide range of interchangeable parts, such as storage bins, shelves, and racks. This allows you to expand or adjust the table at any time as your assortment or workflow changes. It doesn’t really matter where you buy your packing table, as long as the materials are high quality. Your table will be used intensively. A strong tabletop that can withstand bumps and scratches will last you a long time.

Tip 2: Create a comfortable and ergonomic workspace

A wide variety of products will pass over your packing table—from large to small, from heavy to light. Adjust the table height to hip level so you can easily place products into packaging without straining. For larger items, you may want to lower the table slightly. If you have multiple packing tables, set them at different heights so each team member can work comfortably. If multiple people share the same table, consider using an adjustable-height table. Regularly check in with your team to ensure they’re working comfortably and make changes as needed.

Tip 3: Use reliable hardware and tools

During packing, you’ll use various devices and tools. To work quickly and accurately, these need to function well. Use barcode scanners that work in low light, sharp scissors, and high-quality tape to avoid frustration and mistakes.

Your packing table will also require specific hardware—for processing pick lists, printing packing slips, or scanning products. You can speed up your workflow by adding helpful tools in addition to the essentials. We divide the types of hardware used at the packing table into must haves and nice to haves:

Must haves

- Desktop computer – view and process your pick lists in real time

- A4 printer – print packing slips, pick lists, and customs documents (if needed). If you use paperless picking and don’t need customs forms, this may not be necessary

- A6 label printer – print shipping labels for packages

Nice to haves

- Barcode scanner – process orders faster than using a mouse

- Wired network – more stable than Wi-Fi for your computer and printer

- Product label printer – since product labels are smaller than shipping labels, having a separate printer saves you from switching label rolls

Want to know which scanners and printers we recommend? Check out our article on packing table hardware.

Tip 4: Keep packaging materials within reach

Keep shipping boxes, tape, and void fill close to the packing table so you can work efficiently without unnecessary steps. Only keep frequently used materials within arm’s reach. Use mounted shelves, bins, and baskets on the packing table for this. Store materials in the same spots at every table to ensure they’re easy to find. Items used less frequently should be stored further away so they don’t get in the way.

Tip 5: Keep the table tidy and clean

To work in an organized way, give every tool a fixed spot and label them—for example, with stickers. This prevents clutter and helps you avoid wasting time searching. To stay productive throughout the day, make it a habit to keep the table clean and tidy. Plan time for this by making cleanup part of the daily routine. Place a trash bin nearby so you can easily throw away packaging waste. A clean workspace ensures every parcel goes out in top shape.

Get the packing table stickers for free

Would you like to receive our packing table stickers for free? Request them here ⤵

Changelog: Manually printing shipping labels and other updates

Manually printing shipping labels

You can now manually print shipping labels directly from a picklist. This is useful when a label wasn’t printed automatically.

If the selected printer supports ZPL labels and a ZPL version of the label is available, a ZPL label will be printed.

Barcode on return PDF

We now show a barcode on the PDF of a return. This barcode can be scanned to open the corresponding return in Picqer—just like with barcodes on picklists.

Improvements to the new picklist page

- On the picklist page, we now display the total weight of all products.

- We've added an indicator when an order is being shipped from multiple warehouses.

- After closing a picklist, a button is now shown to go directly to the next open picklist in a batch.

Other improvements

- You can now disable product imports for any webshop if you don’t want Picqer to import product data.

- In the new main menu (experimental feature), the “Backorders” menu item is now always visible, along with the total number of backorders. The "Purchasing and replenishment strategy" menu item has been renamed to "Stock strategy" and the "Warehouses" page has been moved to the settings page.

- The current pick stock is now shown in the PDF version of the refill advice.

- URLs in order fields are now clickable from the picklist.

- We’ve added a new API endpoint that allows you to fetch only products with stock in a specific warehouse—ideal for stock syncs.

- We’ve added the webhook

picklists.changed. This triggers when the status, urgency, or assigned user of a picklist changes, or when a product is removed. - You can now transfer stock reserved for backorders to another warehouse.

- In the location history, you can now see who linked the location during a stock transfer in the app.

- In a standard batch in the app, you can now scan picking containers to check off product quantities.

- Searching for customers and shipments has been significantly sped up.

- You can now also search shipments by recipient name.

- VVB orders are now only snoozed if the customer explicitly selected a later delivery date.

- Sendcloud error messages now include detailed feedback from the carrier.

- The settings, purchasing tools, and reports pages now use Picqer’s updated design.

Optimize your warehouse layout with the ABC analysis

Warehouse staff in webshops walk a lot. If you want to work faster, you need to reduce the distance you walk. A smart warehouse layout can help with that. With an ABC layout, you organize your warehouse so that the products you pick most often are placed in the most accessible locations.

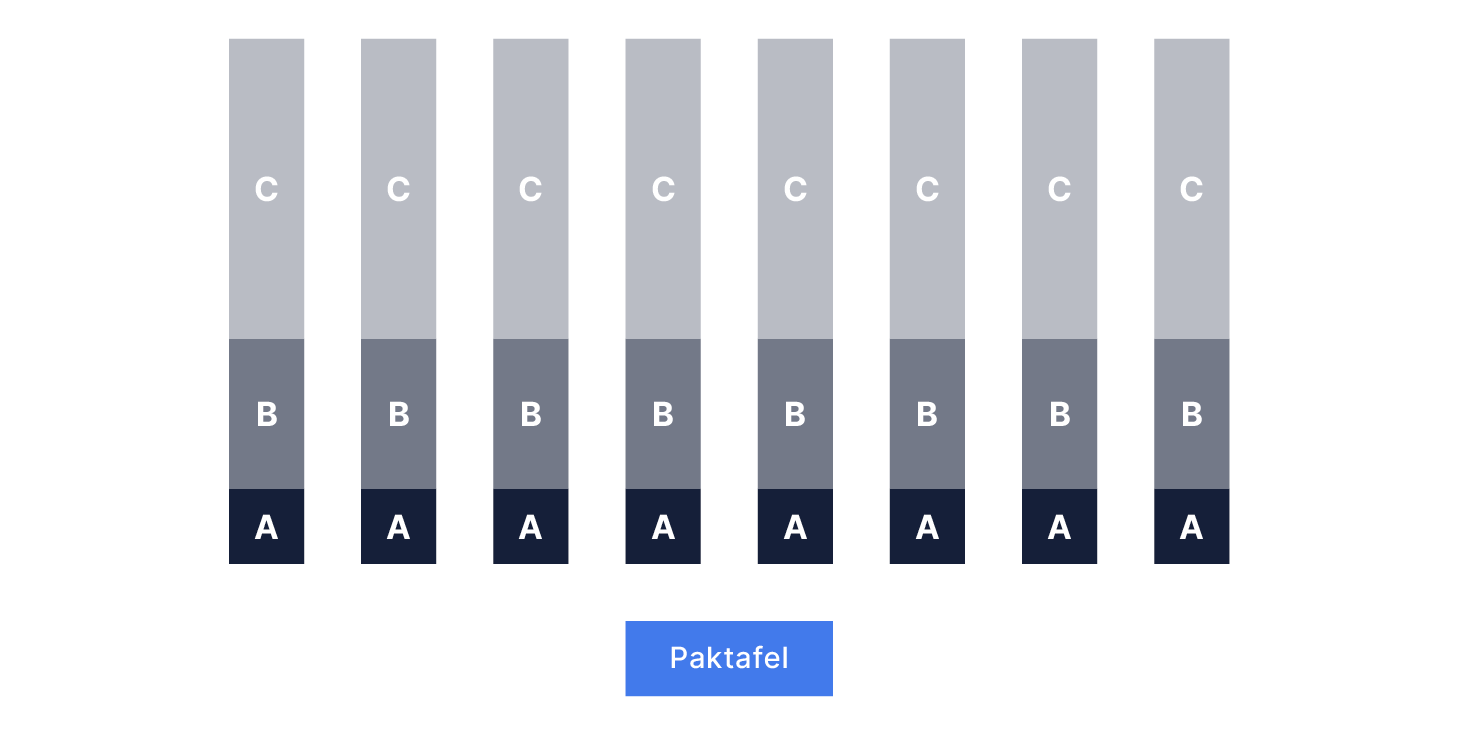

What is an ABC layout?

An ABC layout categorizes your products into three groups. Category A contains the small group of products you sell the most—your top sellers. Category B contains the larger group of products you sell moderately often. Category C contains the largest group of products you sell the least—the long tail.

In an ABC layout, you place A-products as close to the packing table as possible. This way, you reduce the amount of walking. B-products are placed slightly further away. C-products go in the locations that require the most walking. Spread A-products across multiple aisles around the packing table so pickers don’t get in each other’s way.

How do you determine your ABC products?

An ABC analysis helps you determine which products belong in each category. It divides your assortment into three groups based on sales volume. You can use different metrics for this. To optimize your warehouse layout, look at how often products appear in picklists instead of total sales or revenue. That tells you how often you need to walk to a product’s location and how much time you can save by placing it closer.

In Picqer, you can do this using the ABC analysis. The analysis automatically assigns each product an A, B, or C label. Based on this, you can place your products in the most efficient location in the warehouse.

How many products fall into each category depends on several factors, such as the size of your warehouse, the dimensions of your products and bins, and the size of your assortment. In Picqer, we use the following breakdown:

- A-products: the top 5% most picked products

- B-products: the next 15% after the A-products

- C-products: the remaining 80%, which are picked the least

Product sales volumes can fluctuate throughout the year. Product life cycles, seasonal trends, and other changes all affect your data. That’s why it’s important to run your ABC analysis regularly. Picqer runs the analysis automatically every week, looking back over the past 28 days.